Teapot Production Process

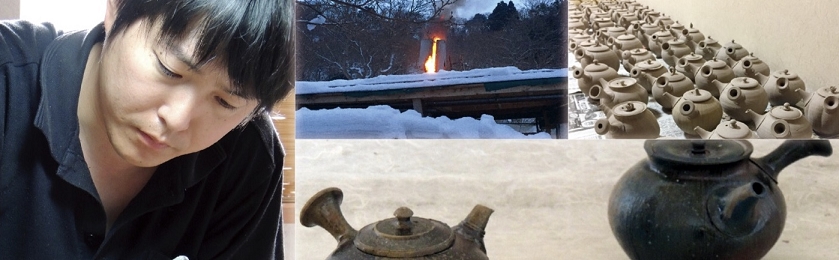

Making teapots requires a lot of work. It starts from preparing the clay, and the process is not yet complete even after baking.

In some instances, some potteries get damaged even after baking.

Of course wheeling skill is essential, yet there are many other factors required to produce a teapot.

In this page, I would like to introduce some part of my teapot making process.

All parts of a teapot, including its body, handle, spout, and lid, are made on the wheel. The thickness is about 2mm.

I also make the tea-strainer one by one with clay, in order that the users can enjoy the true flavor of tea, which cannot be tasted with teapots with common metal strainer.

To prevent leakage occurring, it takes extra care in making the spout. The lid needs to be made perfectly fit to the body.

Milling, grinding, puncturing, jointing, firing, polishing… it requires much work to the completion.

Form the body using wheeling |

All these are made using wheeling |

Grinding |

The tea-strainer - each hole is carefully punctured one by one |

The tea-strainer made separately |

Jointing |

Carefully forming the spout |

Adjusting the socket so that the lid would fit perfectly |

Failures will return to the clay again |

Teapots waiting to be set in the kiln |

|

|

|

|