農機設計の授業がアイオワの農業誌に紹介される!!! 戻る

Iowa Agriculturist : March /April. 1966 4-5 page, OUTLET FOR YOUNG INVENTORS

Ag- Engineers Design New Machinery

Compiled by Bob Dunaway, Ag. J1. 4

Picture 1.

Working out technical problems with the frame of the self-loading manure spreader from left: David Olson, Joe Evans and Mark Peterson. Dr. W. F. Buchele advises.

Picture 3.

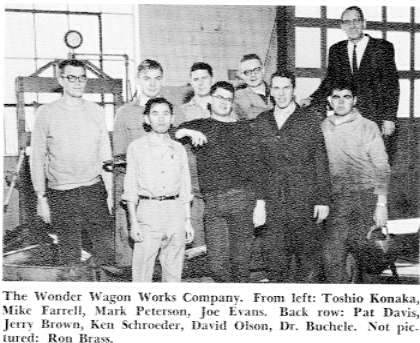

The Wonder Wagon Works Company. From left: Toshio Konaka, Mike Farrell, Mark Peterson, Joe Evans. Back row: Pat Davis, Jerry Brown, Ken Schroeder David Olson Dr. Buchele. Not pictured: Ron Brass.

IF YOU'VE BEEN looking for a practical course at Iowa State, you may want to take Agricultural Engineering 436, better known as "Agricultural Machinery Design." One quarter each year a group of agricultural engineering students takes the course aimed at designing and building an entirely new piece of farm machinery. Last quarter, nine students designed and built a self-loading manure spreader. Decisions to build a new piece of machinery don't just "pop up." The first week of the class was spent in brainstorming sessions. Over 100 possible machines were listed and discussed as possible machines that the farmers really need. They picked the self-loading spreader because of the increasing popularity of concrete feed lots, says Dr. W. F. Buchele, professor of agricultural engineering in charge of the course. When the spreader had been chosen for the project, the members of the class formed a small company among themselves to make things run smoothly. Adopting the name "Wonder Wagon Works," they broke the company into three departments-Service, Elevator and Chassis. Buchele was elected company president with David Olson selected as Chief Engineer. For Assistant Chief Engineer the group chose Ron Brass who also served as manager and chief of layout in the Elevator Department. Ken Schroeder was' in charge of building the elevator frame. The chain and drive apparatus for the elevator was supervised by Gerald Brown. In the Chassis Department, Chief Olson was supervisor. Mike Farrel and Mark Peterson constructed the box and frame. Toshio Konaka from Japan, built the winch. Joe Evans handled the layout. The Service Department included Pat Davis, in charge of purchasing. He also worked as a consulting engineer and draftsman. Evans rounded out the Service staff as a draftsman. After these details had been worked out, each student submitted two or three possible designs for the spreader.

The best design was selected and the process of drawing up the final plans began. Operating on a budget of about $150, the students dug around for parts that might be used on the spreader. Most of the parts came from salvage yards, from old machines and the department's stockpile of used parts. During final exams, the students finished their part of the project by writing a complete report on their work during the quarter. The report, including photographs, was sent to the Iowa Development Commission and to machinery manufacturers for study. The machine itself will be turned over to the Center for Industrial Research and Service (CIRAS) at Iowa State or to the Development Commission. The Iowa State University Research Foundation will determine its patent potential. Although the self-loader would work on dirt lots as well as concrete, it wouldn't be as efficient on dirt, where the old method of scooping the manure with pitch fork or tractor loader and dumping it into the spreader is still the common practice. But, with more and more people turning to concrete, says Dr. Buchele, a machine of this type should be popular.

The self-loading device works something like an elevating scraper. A conveyor located along the front of the machine scrapes the manure from the lot as the spreader moves along and elevates it into the box. Past members of "Agricultural Machinery Design" have turned out such things as a high speed mower, a snow-blower attached to the front end of a manure loader, a self-unloading device for wagons, a corn stalk chopper and ear corn granulator and a hay hoisting winch. Not long ago the students in this class produced a device which automatically couples the PTO shaft and hydraulic couplings of a tractor to the machine it is pulling. This idea is now being developed by the farm machinery industry. A rotary tiller-planter built in 1961 is now produced and marketed by a manufacturer. "The important thing about this course " says Buchele, " is that the students follow an idea from the time it is conceived right through to the actual construction. Also, they design their machines from what is available at the time. The things these students do later become real machines of value to farmers." Sometimes the agricultural engineers come up with inventions, sometimes innovations, but it's always a good way to learn.