C8051F300 (Silicon Laboratories)

![]() Overview

Overview

![]() Hardware

Hardware

![]() Software

Software

![]() Software Down

Load

Software Down

Load

![]() Reference

Reference

![]() Acceleration sensor

input

Acceleration sensor

input

![]() PWM setup for

Servo Motor

PWM setup for

Servo Motor

![]()

Updated on

May 18, 2002 ----

Added G-sensor and PWM explanation

![]()

May 14, 2002

---- Started the project

![]()

C8051F300 / Overview

![]()

![]()

Related information

Cygnal

http://www.cygnal.com/default.htm

We can reach following site as Silicon Laboratories Inc.

http://www.silabs.com/tgwWebApp/public/index.htm

http://www.silabs.com/products/microcontroller/mlp_matrix.asp

Development Environment

I have following "Development kit".

http://www.silabs.com/tgwWebApp/public/web_content/products/Microcontrollers/en/C8051F300DK.htm

http://www.silabs.com/products/microcontroller/C8051F300DK.asp

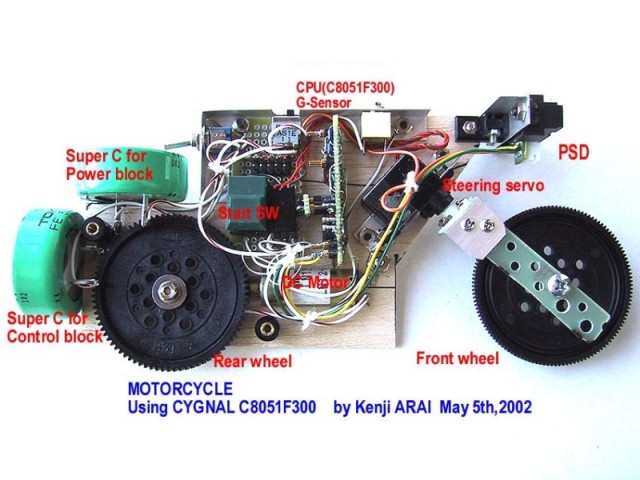

Example project

I made miniature

Motorcycle as an application but I couldn't finish it yet.

Basic

Function

Control items are;

・ Control for driving force by small DC motor

・ Control for steering by servo motor

For this purpose, following devices are used as sensors.

・ PSD sensor for detection of front obstructions

・ X-Y axes acceleration sensor for trim

control

In addition for this;

・ Monitoring function by radio transmitter

All of this functions are controlled by C8051F300.

![]()

C8051F300/ Hardware

![]()

![]()

Hardware

structure

You can reach a circuit drawing as below.

Circuit Diagram(2 pages)

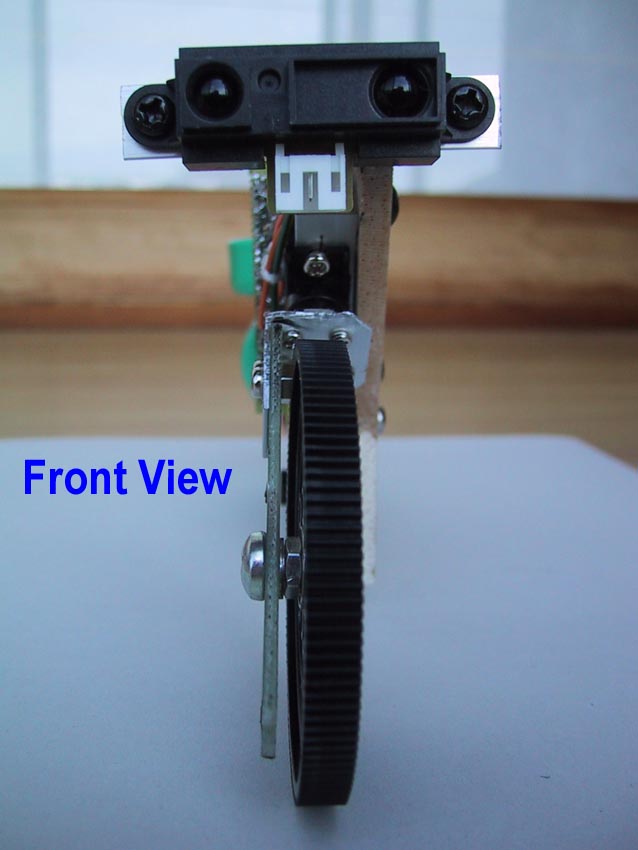

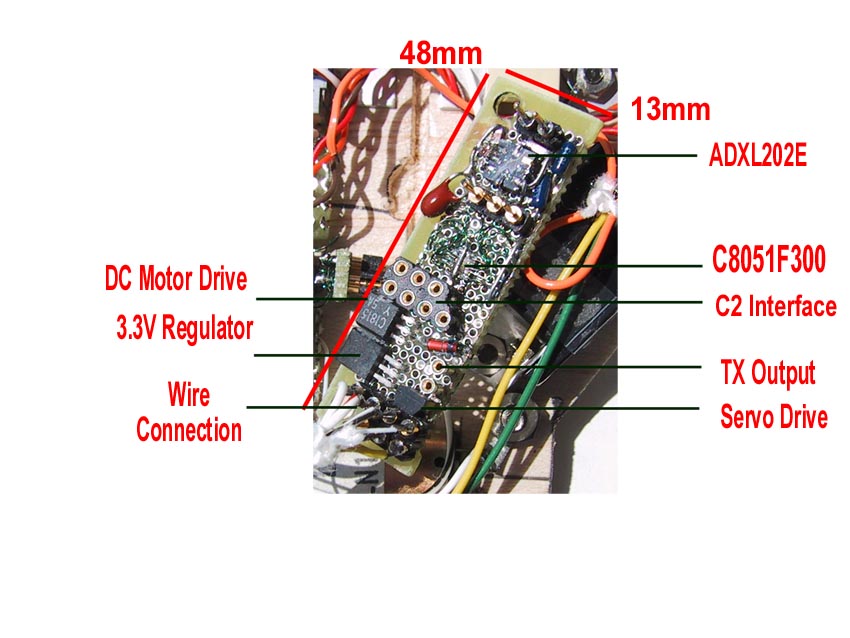

C8051F300 is in very small package so it's

very difficult to handle. I recommend to use DIP type

evaluation chip for amateur hobby purpose. You cannot

see 3mm x 3mm chip in the picture.

CPU has a clock oscillator in the chip so you don't need

any additional circuit and pins for the clock.

I'm using acceleration sensor made by ANALOG DEVICES, ADXL202E. This is also very small only 4.5mm x 5mm. ADXL202E

outputs PWM pulse as acceleration related data. F300 has PCA

module (Programmable Counter/Timer Array) for three

independent channels. In the project, two channels are used

for PWM data input from ADXL202E as input capture function

and another channel is used for 16Bit PWM Output as

steering servo motor control.

F300 ADC is used for PSD(Sharp GP2D12) input. PSD output

voltage range is from 0V to 2.6V. Every 38.3mS (typ.), PSD is

updating output. So I set 20mS sampling time for PSD data

processing but this is very slow sampling time because F300

has 500ksps capability.

Power consumption point of view, PSD is not so good because

it spends 50mA (max.). DC motor is only 10mA (no load

condition) and F300 and ADXL202E are only fee mA.

Wireless serial communication is not regular application.

This is just for your reference.

I use AM-RT5-418(AM Hybrid

Transmitter - RF Solutions) and AM-HRR3-418(AM Hybrid Receiver). It recommends 2400bps but

I used it as 9600bps speed.

![]()

C8051F300 / Software![]()

![]()

I'm using Keil C compiler for

Software development. F300DK includes both hardware (evaluation

board) and Keil software.

I couldn't finish the development (and never end ?) but

followings are temporary results.

(a) PSD signal processing using ADC function

(b) Acceleration detection using

G-sensor siganl to F300 PCA function

(c) Servo motor control using PCA PWM function

(d) DC motor speed control

using F300 TIMER2 function

(e) Data transmit

function using F300 UART0 and wireless TX module

C8051F300

Know-How (Programming tips)

(a)PCA 16bit Software Timer

F300/1/2/3 manual

said in page 137;

Important Note About Capture/Compare Register: When writing a

16-bit value to the PCA0 Capture/Compare registers, the low

byte should always be written first.

C compiler creates two byte code by opposite byte order.

If I write C-code as below;

if ( CCF2 == 1){

// -------- Module 3 ------------------------

if ( pwm_period

== 0 ){

PCA0CP2

= pwm_data;

}

CCF2 = 0; // For just in

case

}

Keil C compiler creates following assembler code. This cannot

follow the rule.

MOV PCA0CP2+01H,pwm_data

MOV

PCA0CP2,pwm_data+01H

Then, I need to modify the source code as below.

if ( CCF2 == 1){

// -------- Module 3 ------------------------

if ( pwm_period

== 0 ){

PCA0CPL2

= (unsigned char)pwm_data; // Set center position of servo data

PCA0CPH2

= (unsigned char)(pwm_data/256); //

(need separate loading method !)

}

CCF2 = 0; // For just in case

}

Code is created as below.

MOV PCA0CPL2,pwm_data+01H

MOV A,pwm_data

MOV

PCA0CPH2,A

This is okay. But I spent half day to recognize it.

(b)

Priority Clossbar Decoder

This is also very important point to use F300

function. Points are;

・ F300 has crossbar

function and need to recongnize which is via a crossbar which

is NOT via clossbar

・ Need clear definition

of each resources (UART,SMBus,SYSCLK,CP0

Output,PCA,T0&T1 and Port Latch data)

It very simple rule but during the debugging, it is very

difficult to judge function setting miss or crossbar setting

miss.

![]()

C8051F300 / Software Down Load![]()

![]()

Control program for C8051(not finished yet)

------- Motocycle

![]()

C8051F300 / Reference

![]()

![]()

Please see overview area

![]()

C8051F300 / Acceleration sensor

input

![]()

![]()

Data sheet(ANALOG DEVICES-ADXL202E) mentioned calculation method for

acceleration sensor as follows.

//

ADXL202 Acceleration data

// |<---data-->|

// |<---------period-------->|

(data/period) - 50%

// _________

________ g = ------------------------------

// |

|

|

12.5%

// ___|

|________|

// t1

t2

t3

(PCA0 counter data)

//

// Overflow process is ignored ( only once is expected)

//

PCA0 module sets input capture mode with both rising and

falling edge then measure free running counter data at t1, t2

and t3 timing ( you can see those part in the below as BLUE PART).

Free running counter is 16 bit length so it becomes overflow

condition. Easy programming method is to match the data

length of F300 PCA and PWM output of ADXL202E. ADXL202E

has an adjusting function using Rset resister value change.

PCA0 clock sets as below.

void PCA0_Init (void)

{

PCA0CN = 0x40; //

Enable PCA counter

PCA0MD = 0x09;

// Sysclk/1, Enable Overflow int.

//

overflow = 2^16 * 1/(24.5 * 1e6)

// = 2.675mS

PCA0CPM0 = 0x31;

// Module0,

//

Both edge mode, enable interrupt

PCA0CPM1 = 0x31; // Module1,

// Both edge mode, enable

interrupt

PCA0CPM2 = 0xcb;// 16bit

PWM mode, comparator function

// Enable interrupt

// PCA0CP2 = SRV_CNTR; // Center position of

servo data

PCA0CPL2 = SRV_CNTR;

PCA0CPH2 = SRV_CNTR/256;

pwm_period = SRV_CNT_N;

}

This is maximum speed for the CPU. Rset is 200K ohm then PWM

base period is;

period = Rset/125Mohm = 200kohm/125Mohm = 200 *1e3 / 125 * 1e6

= 0.0016 [sec] = 1.6 [msec]

I measured raw data from acceleration sensor using following

test program.

void show_acc_data( void )

{

unsigned int dt0, dt1;

if ( x_ready == 1){

EA = 0; // disable

interrupts

dt0 = x_period;

dt1 = x_data;

EA = 1; // re-enable

interrupts

PutCRLF(); // Display T = xxxxmS

PutStr("Txp= ");

// show_time_data( dt0 );

show_time_data( x_period );

PutStr("d= ");

// show_time_data( dt1 );

show_time_data( x_data );

}

x_ready = 0;

if ( y_ready == 1){

EA = 0; // disable

interrupts

dt0 = y_period;

dt1 = y_data;

EA = 1; // re-enable interrupts

PutCRLF(); // Display T = xxxxmS

PutStr(" Typ= ");

// show_time_data( dt0 );

show_time_data( y_period );

PutStr("d= ");

// show_time_data( dt1 );

show_time_data( y_data );

}

y_ready = 0;

}

void show_time_data( unsigned int dt )

{

putchar(dt/10000 +'0'); // 10^4

dt = dt - (( dt / 10000 ) * 10000);

putchar(dt/1000 + '0'); // 10^3

dt = dt - (( dt / 1000 ) * 1000);

putchar(dt/100 + '0'); // 10^2

dt = dt - (( dt / 100 ) * 100);

putchar(dt/10 + '0'); // 10^1

putchar(dt%10 + '0'); // 10^0

PutStr(" mS ");

}

Using this program, I calculated

measured data as Here. Average data is 36,893.

period = 36893 * (2.675msec/ 2^16) = 36893 * (2.675*1e-3/65536)

= 36893 * 40.817 * 1e-9 = 1505.87 [usec] = 1.506 [msec]

If I use this value, free running counter overflow is zero or

once per measurement. Then we don't need to consider overflow

itself. We can just calculate it using unsigned 16bit

data.

static unsigned int

t1_x, //

Rising edge data for starting

t2_x, // Falling edge data

t3_x, // Rising edge data for ending

t1_y, // Same rule as X-axis

t2_y,

t3_y;

void PCA0_ISR (void) interrupt 9 using 3

{

if ( CF == 1 ){ //

-------- PCA0 Overflow -------------------

deleted;

}

if ( CCF1 == 1 ){ //

-------- Module1 -------------------------

if (X_IN == 1){ //

Measure rising edge data

t3_x = PCA0CP1;

// Read caputure data from

Module0

x_period = t3_x - t1_x;

// Calculate cyclic time

x_data = t2_x - t1_x;

// Calculate acceleration data

t1_x

= t3_x;

// Save data for next mesurement

x_ready = 1; //

Set ready flag

} else { //

Mesure falling egde data

t2_x = PCA0CP1;

// Read caputure data from

Module0

}

CCF1 = 0;

// Clear interrupt source

}

if ( CCF0 == 1 ){ //

-------- Module2 --Same as Module1 -------

deleted;

Normalization is in here as "calcu"

sheet.

//------------------------------------------------------------------------------------

// Normalization of Acceleration Data

//------------------------------------------------------------------------------------

// G = (data/period

-50%) / 12.5% [G]

// = (data/period * 100 - 50) / 12.5 [G]

// = (data/period * 100 - 50) * 1000 / 12.5 [mG]

// = (data/period * 100 * 1000 - 50 * 1000) / 12.5 [mG]

// = data * 1000 * 10 / period * 100 / 125

- 50*1000 / 12.5 [mG]

// = data * 10000 / period * 100 / 125 -

4000 [mG]

//

void nor_acc_data( void )

{

unsigned int dt0, dt1;

if ( x_ready == 1){

EA = 0; // disable interrupts

dt0 = x_period;

dt1 = x_data;

EA = 1; // re-enable interrupts

x_g =(int)((unsigned

long)dt1 * 10000L / (unsigned long)dt0 * 100 / 125) - 4000;

}

x_ready = 0;

if ( y_ready == 1){

EA = 0; // disable interrupts

dt0 = y_period;

dt1 = y_data;

EA = 1; // re-enable interrupts

y_g =(int)((unsigned

long)dt1 * 10000L / (unsigned long)dt0 * 100 / 125) - 4000;

}

y_ready = 0;

}

Collection of normalized data is here (Sheet 0429_data_1 & 0429_data_2). Result is below.

X1

Y1 X2

Y2

Ave -75.37

-1082.40 870.33 -185.28

Shiguma 6.83 7.70 8.21 10.62

Max -60.00 -1058.00

897.00 -161.00

Min -113.00

-1105.00

848.00 -219.00

Diff

53.00 47.00

49.00

58.00

EXPECTED

DATA 0.00 -1000.00 1000.00 0.00

![]()

![]()

C8051F300

/ PWM setup for Servo Motor

![]()

![]()

I'm using following servo motor.

・Company: Grand Wing Servo-tech Co.,Ltd.

・Web:

http://www.grandwing.com(I couldn't reach the Web site)

・Type: PICO F/BB

Neutral position needs 1500 microS active pulse width. PCA0

cannot set clock source three channels independently. PCA0

already uses for PWM input capture for acceleration sensor.

So PCA0 Channel #1 also needs to use same clock and use for

16bit PWM output. Servo motor is well designed for only affect

active pulse width. We can keep cyclic period around 15mS to

20mS.

Cyclic period is controlled by software with rough accuracy. RED PART is PWM setting and BULE PART is overflow control.

void PCA0_Init (void)

{

PCA0CN = 0x40; //

Enable PCA counter

PCA0MD = 0x09;

// Sysclk/1, Eable Overflow int.

// overflow = 2^16 * 1/(24.5 * 1e6)

// = 2.675mS

PCA0CPM0 = 0x31; // Module0,

// Both edge mode, enable interrupt

PCA0CPM1 = 0x31; // Module1,

// Both edge mode, enable interrupt

PCA0CPM2

= 0xcb;// 16bit PWM mode, comparator function

// Enable interrupt

// PCA0CP2 = SRV_CNTR;

// Center position of servo data

PCA0CPL2 = SRV_CNTR;

PCA0CPH2 = SRV_CNTR/256;

pwm_period = SRV_CNT_N;

}

PWM data is only for active pulse width as mentioned before.

Max and Min data is very important for the servo motor

because over range will be made a damage for plastic gear in

the motor. I broke one servo motor during debugging. You are

better to minimize following data as small as you can.

#define SRV_CNTR 36750 // 1.5mS * 24.5MHz = 39200

counts

#define SRV_MIN 19600 // 0.8mS * 24.5MHz = 19600

counts

#define SRV_MAX 58800 // 2.4mS * 24.5MHz = 58800

counts

Following is debug program. PSD data connects servo motor

data then you can check with you hand front of PSD.

//------------------------------------------------------------------------------------

// Show ADC data

//------------------------------------------------------------------------------------

// Vref = VDD = 3.28V

// Scale = 3.28 * 255/256 /256 [V/bit]

// = 3.28 * 255/256 /256 * 1000 * 1000 [mV/bit]

// = 12813 *255/256 [mV/bit]

// = 12763 [mV/bit]

//

void show_anlg_data( void )

{

long volt_dt; // ADC data (mV)

unsigned int dt;

EA = 0; // disable

interrupts

volt_dt = acc_ana;

EA = 1; // re-enable

interrupts

volt_dt = (volt_dt * 12763L) / 64000L;

show_volt_data( (unsigned int)volt_dt );

// ********** DEBUG *********** //

dt = SRV_MIN + (unsigned int)volt_dt * 14;

if ( dt > SRV_MAX ){

dt = SRV_MAX;

} else if ( dt < SRV_MIN ){

dt = SRV_MIN;

}

pwm_data = dt;

}

Overflow condition is controlled by following program.

#define SRV_CNT_N 6

// Servo PWM cycle counter

void PCA0_ISR (void) interrupt 9 using 3

{

if ( CF == 1 ){ // -------- PCA0

Overflow -------------------

if

( pwm_period == 0 ){

pwm_period = SRV_CNT_N;

} else {

pwm_period--;

}

CF = 0;

// Clear Overflow flag

}

if ( CCF1 == 1 ){ // -------- Module1

-------------------------

deleted;

CCF1 = 0;

// Clear interrupt source

}

if ( CCF0 == 1 ){ // -------- Module2 --Same

as Module1 -------

deleted;

CCF0 = 0;

}

if ( CCF2 == 1){ // -------- Module 3

------------------------

if ( pwm_period == 0 ){

PCA0CPL2 = (unsigned char)pwm_data;

// Set center position of

servo data

PCA0CPH2 = (unsigned char)(pwm_data/256);

// (need separate loading method !)

// PCA0CP2 = SRV_CNTR;

// Don't use this

command !!

} else {

PCA0CPL2 = 0; // Set

center position of servo data

PCA0CPH2 = 0; // (need

separate load !)

}

CCF2 = 0; // For

just in case

}

}

In the program, six interval is counted (RED PART) then if it's zero, PWM interrupt is enable to

set active pulse (BLUE

PART). We can set 19mS (2.675mSec

* 7 = 18.725mSec).

![]()

![]()